State of the art infrastructure

With cheap products available internationally we have to face cut-throat competition. Customers have more choice than ever before. This necessitates that the organization must be highly flexible, efficient and infrastructure must be up to the mark.

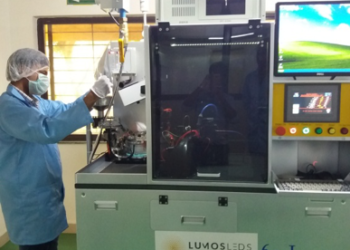

Lumos LEDs is equipped with state of the art machinery imported from Japan. We have one of it’s kind Gold Wire bonder which is the life of any SMD Led Process.

Our process

- Wafer Expansion

- Die Attach

- Gold Wire Bonding

- Clear/Phosphor Epoxy

- Testing and Binning

- Taping and Reeling

More about our facilities

- In-house testing facilities to test and maintain AEC-Q qualified SMD LED’s

- Life Test up to 50000 hours, accelerate life test, high temperature test upto 110 degrees, Low temperature test up to -30 degree.

- Die shear test and gold wire pull test on a weekly basis to ensure optimum quality.

- Use only automotive qualified wafer form Epistar for consistent quality with zero rejection.

- Installed capacity to produce 1 million and LED’s per day.